Abrasive Blasting

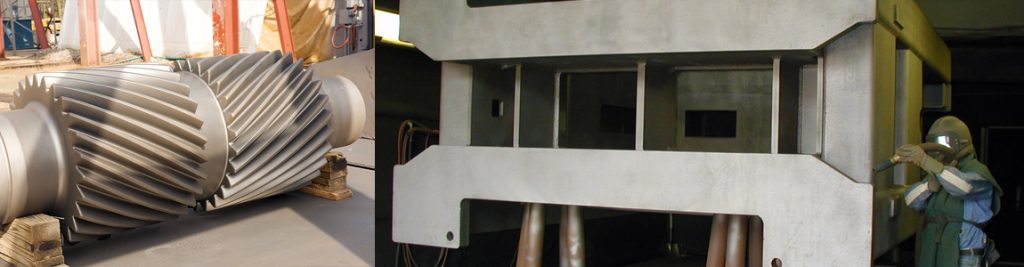

(left) 20,000 lb. Mil Pinion after blasting at Derrick.

(right) 40,000 lb. Machine Base being blasted and prepped for paint.

Abrasive, Sand & Bead Blasting in Cincinnati

Abrasive Blasting

THE BEST METHOD TO IMPROVE ADHESION & INCREASE COATING LIFE

Paint and coating manufacturers recommend Abrasive Blasting as the best method to prepare surfaces prior to the application of their products due to its ability to remove surface contaminants while also imparting an anchor pattern/profile to the substrate, which greatly improves adhesion. Abrasive blasting reduces surface prep time compared to manual hand tool cleaning, from hours to just a fraction of the time. Derrick offers a variety of blasting methods and blast media to customize the surface prep process to meet your precise specifications.

| Area | Size (WxHxL) |

|

|

Sand Blasting

Sand blasting has several different benefits and it’s by far the most common way of sanding and cleaning a metal surface. Sandblasting is well-suited for the removal of rust, cleaning metal, and smoothing it. Removing the rust on metal is imperative to many metal equipment and structures because rust can severely damage surfaces. Think of rust like it’s the scourge of many, many pieces of metal.

Sandblasting cures the rust, though. It can actually remove damage and get equipment into good working condition again. Properly removing rust from your metal is the single most important step we can help you take to ensure that your surfaces have a long life span and is in the best condition it can be in.

Additional Sand Blasting Benefits

- Harmful Surface Contaminants Are Eliminated by Blasting

- Blasting Improves Speed and Accuracy in Laser Cutting

- Life of the Laser Eye is Extended by Blasting

- Cleaning Time is Reduced from Hours by Hand, to Minutes by Blasting

|

BLAST ROOMSDerrick has four large blast rooms to process very large, medium, and small industrial components. We also have tumble and table blast machines for processing smaller and high volume parts.

|

| Area | Size (WxHxL) | Type |

| Blast 1 | 11′ x 9′ x 30′ | Air Blast |

| Blast 2 | 15’6″ x 13′ x 40′ | Air Blast |

| Blast 3 | 9′ x 16′ x 40′ | Air Blast |

| Portable | 10′ x 12′ x 16′ | Air Blast |

| Tumble Blast | 6 cubic feet | Wheel Blast |

| Table Blast | 96″ diameter | Wheel Blast |

Local Sand Blasting

- Steel Shot/Grit

- Star Blast

- Garnet

- Aluminum Oxide

- Boiler Slag

- Glass Bead

- Custom Specified

These items are propelled to remove contaminants and give either a deep profile or smooth surface cleaning that can’t be matched by hand. A field that often uses abrasive blasting to its advantage is Laser Cutting. It can improve the life of the laser eye, along with the speed and accuracy of the machinery. Frames, metal, and other large and small equipment is frequently blasted in our facilities. To give you an idea, items as small as a single 5 pound part, to a 50 ton piece of equipment can be handled. It’s important that blasting is done the proper way, and we offer peace of mind with our membership in The Society of Protective Coatings (SSPC).

Bead Blasting

What is Bead Blasting used for? There are a lot of different ways to treat and work with metal parts of all sizes. Bead blasting can use media that are metal, glass, or ceramic to treat the surface of stone and various types of metal. It is sometimes also referred to as shot peening. Abrasive blasting methods like this are particularly useful for a variety of jobs, such as resurfacing, strengthening, and even cleaning of tough surfaces. Resurfacing Abrasive blasting is using an abrasive material that is propelled toward a surface at a high speed. For resurfacing projects, this can help create a unique texture and design on a given material. It can also be used in order to prepare surfaces for subsequent treatment, such as painting. Items that might need to be resurfaced include:

- Car parts, to remove old paint before a new paint job

- Airplane parts before painting

- Stone or cement for a construction job

- Aluminum for construction purposes

Strengthening Bead Blasting: is often used to help increase the strength of metal materials. A common place to see this done is with firearms. Owners may opt to subject the barrel of a firearm to some peening, which often can dull the finish and allow it to take paint a little easier. Aircraft parts are also subjected to such blasting in order to increase the parts’ toughness against fatigue.

Cleaning Using Bead Blasting: At Derrick Company, our blast rooms can take on parts of many different sizes. This is great for individual parts that need to be blasted for resurfacing or strengthening purposes, but blasting can also be a great way to clean items. If you bead blasted the tile and grout in your pool, for example, you just might be able to get rid of some of those stubborn calcium deposits and fungus. Bead blasting can be used for a variety of purposes. There is very little to clean up after a blasting job, and it can make a clean-up job go several times faster.

Additional Types of Abrasive Blasting

Wet Abrasive Blasting: also called vapormatting, wet abrasive blasting involves using a wet process to take extremely fine or coarse materials and using hot water and soap to allow for degreasing and blasting. The idea is to eliminate dust and/or things like hazardous material or waste and to do so without danger. Examples include removing asbestos or radioactive components. Things that might need wet abrasive blasting include kitchen cabinets and commercial dishwashing machines.

Automated Blasting: automated blasting refers to the automation of abrasive blasting.

Dry Ice Blasting: is the process of pressurizing air and dry ice; the material is meant to be cleaned without ruining the properties of it. The dry ice modifies to leave no after-residue for clean up.

Hydro-Blasting: as you guessed it, is the utility of using highly pressurized water to remove things such as buildup or old paint.

Wheel Blasting: as the name suggests, a wheel is used to blast and propel the abrasive against the object being changed. No gas or liquid is used in wheel blasting.

Micro-Abrasive Blasting: uses small nozzles to run a stream of abrasive to a small and very specific area, position or part on a larger part or area.

Contact Derrick Co

If you are in need of any of these blasting services, Get in Touch with us today!